Jared was just a guy in Operations,

His drone designs lacked variations,

One day he found Fusion 360,

And arrived at the conclusion,

It could really upgrade his creations!

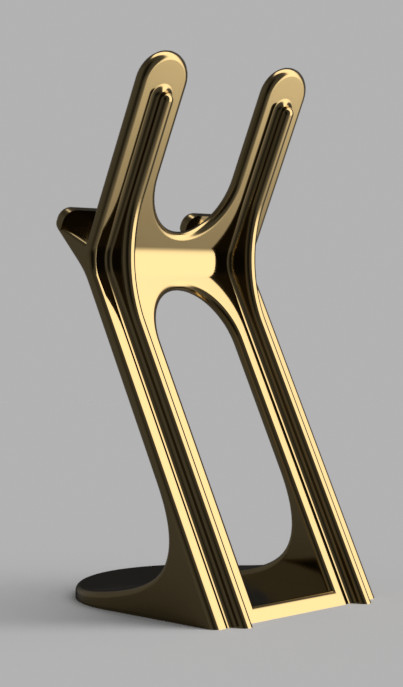

As I walked through the D3 headquarters on that otherwise normal Tuesday afternoon, still jet-lagged and half asleep, a subtle detail jumped out at me. I had seen that cell phone stand before. In fact, I had seen several versions of it on various desks around the office.

Where did it come from? Who was responsible for this apparently viral piece of office equipment? And why hadn’t I gotten one?

As you may have guessed from the introductory limerick, the guy responsible is Jared. (Yeah, about that.. I know I promised no more puns or bad rhymes on the blog – blame the recent trip to Ireland, not me.)

Jared doesn’t have a design background. He is on D3’s operations team, and spends more time in spreadsheets and code than in 3D design software. And yet, somehow Jared was responsible for designing and 3D printing the latest designs I saw in front of me. How did Jared get on the Fusion 360 bandwagon? Well, I interviewed him to find out.

Me: So, Jared, thanks for sitting down with me! What I want to know first is, where is my phone stand? Don’t I get one too?

Jared: Well, what color do you want? I’m taking orders now!!

Me: Ok, well let’s talk about that later. Back on topic, when did you first hear about Fusion 360?

Jared: Well, it was actually while I was working here at D3 (big surprise!). My company realized that Fusion 360 was going to be a big part of the future and so they started investing in it. About that time my coworker RyJo told me I should check into Fusion 360 instead of my janky 123D tools.

To be honest, the first time I opened Fusion 360 it looked complicated and so I closed it and went back to 123D.

Me: What?! (I jump out of my chair in surprise) Why would you go back to less capable products that were going to be discontinued anyway?

Jared: Honestly, I thought of Fusion 360 as the professional tool, and thought 123D was the creative tool. You could say I saw Fusion 360 more like a big desktop computer, heavy and complex, and 123D more like a tablet, light and creative.

But when I heard 123D was being discontinued, I guess I saw the writing on the wall and decided, why wait any longer?

Me: So how did you get going in Fusion 360 this time around?

Jared: So at first, I was just using it like 123D, lots of direct edits and combining bodies, not using parameters or anything. I would design what I thought I wanted, 3D Print it, test it, then cut or add material, and repeat until I had something that worked.

I knew I needed to learn more though. I saw some of the stuff RyJo was modeling in Fusion 360 and I knew I could do more. There were several things that helped me take it to the next level.

- I had some Saturday “Coffee and Fusion” sessions with RyJo. I was kind of blown away when I saw some basic stuff I wasn’t using yet that could completely change my workflows. I didn’t really think I needed training, but this showed me the value in it.

- I started reading these Blog articles to see what other people were doing with Fusion 360 and get some news on features I didn’t know about.

- I started looking for articles and videos on the Autodesk Knowledge Network, those helped a lot too.

- I ran through the Jumpstart Guide D3 keeps advertising after their blog posts. By the way, when are you releasing the fourth one?

Me: I’m in charge of this interview, I’ll ask the questions here!

Jared: Ok, ok, in due time I’m sure.. Really though, besides all the stuff I just mentioned, I think it really drives you to learn more and improve your skills when you’re building your own stuff in Fusion 360, or building something you’re passionate about. I took my skills to another level trying to apply stuff I was learning from all those channels on my own design projects.

Me: Like the famous cell phone stand (which I still haven’t received by the way).

Jared: Let’s see how much you butcher this interview on the blog, then we’ll talk.

Anyway, back to what I was talking about before you interrupted me. Also, for me what helped me push my creativity was investing in my own 3D printer to be able to model something and immediately go and make a real 3D prototype, that made it very exciting. I could iterate much faster than when I was relying on a friend in my drone club to 3D print stuff for me when he had time. I wasn’t stressed about getting it right the first time or worried about wasting my friend’s time and filament anymore.

When I got into Fusion 360 this was really a great benefit for me.

Me: So, about this phone stand. I noticed several different versions.

Jared: Yep, I definitely had a few. I’m up to version 5 now. At first, I built it to split in pieces so it would be easier to print, and then I would fuse the pieces together. I wanted to make it all in one print to be simpler, so I modified it again. After discussing the design with various people, I decided I needed to adjust it to make it stronger. It bounced on the desk any time you touched it. In version 4 I really liked the look of the design, but it still wobbled too much.

I made some renderings in Fusion 360 and pulled them up on my app at work to talk over the problem with some of our designers. I got some great engineering advice to add some gussets along the long flat arms, and this really helped it a ton. This thing is solid now!

Me: Awesome. I like that you used the app! To me the app is one place we really see the next-gen CAD side of F360. What was the very first thing you designed in Fusion 360?

Jared: The first thing I made and printed was a part to fix the railing inside my refrigerator door. It was exciting designing and making my own part instead of going traditional and buying a replacement part.

After that I started making parts to upgrade my drone. Stuff like new camera mounts or new redesigned arms when mine broke.

Me: Surely you don’t mean you crashed your drone. I thought you were a good pilot.

Jared: Everybody crashes their drones. And yes, that’s how arms break most of the time.

Me: We’ll just pretend that’s true for now and move on. So, what’s next for you with Fusion 360?

Jared: Now that I have the phone mount done for my desk, I’d like to design a mount for my car. I’m not naming any names, but RJ modeled one of the coolest phone mounts I’ve ever seen for a car.

Me: Why thanks Jared, it’s so great to hear you liked that design so much. I definitely didn’t add anything to this transcript at all.

Really though, it’s cool to see your journey from writing off Fusion 360 at first to now using it for increasingly cool and complex designs. Thanks for taking a minute to sit down with me! I think people will enjoy hearing about this interview and, who knows, maybe it will help someone to take their design to the next level also! Thanks Jared.