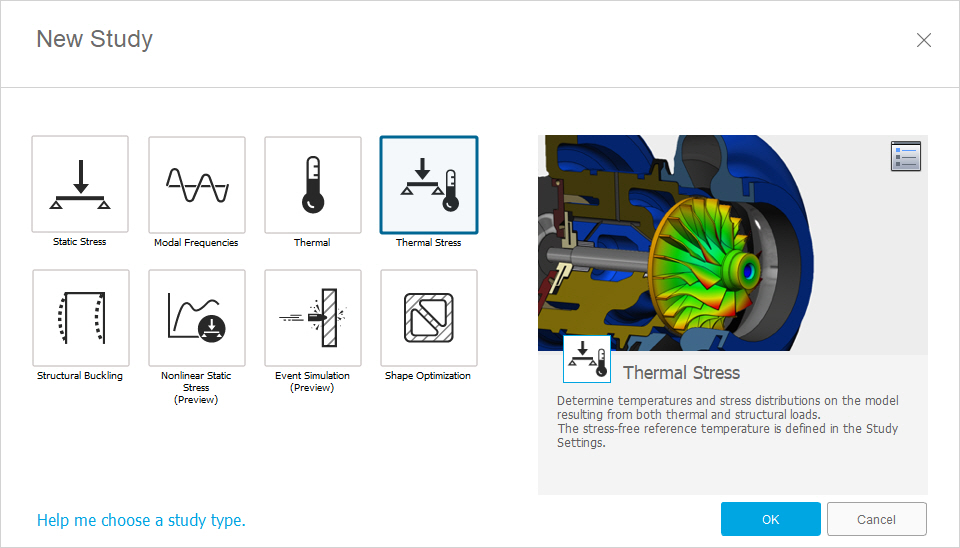

Last week I was at the annual Autodesk training in Denver, CO. We get to do a lot of hands-on review of what’s new in the latest releases of software as well as get reinforcement on the latest strategies and stuff, you know, like Jedi training for the Autodesk channel. So, there I was sitting in a session for Nastran In-CAD, which, if you don’t know, includes very advanced and awesome simulation tools that run straight inside of Inventor or SOLIDWORKS.

After the first hands-on exercise started, I thought, I wonder how these workflows would play out in Fusion 360? So, as any good tech guy trying to think outside of the box would do, I deviated from the instructions. As most of the room moved forward with the exercises inside Inventor, I opened up Fusion 360 to go through the steps in a parallel universe. I’m not sure anyone noticed or cared, there may have even been a few people asleep somewhere behind me. But I thought, I have other coworkers going through the Nastran stuff so it’ll be fine, YOLO!

Before I go any further let me make one thing clear. I’m not going to tell you to throw away your current CAD tools here, or even to choose Fusion 360 simulation over Nastran In-CAD tools. I’m not saying Fusion 360 is for the Jedi where Nastran is for the Storm Trooper. The main point of my experience is something else.

So, what did I find out through my experiment?

- I was able to follow along every single exercise using Fusion 360 in parallel with the class.

- In many cases I was able to set up the study quicker than others in the class.

- I pushed my simulations to the cloud and then could continue working on alternate study setups while the solve was calculating. I still got results back in the amount of time it took others in the class to finish local solves.

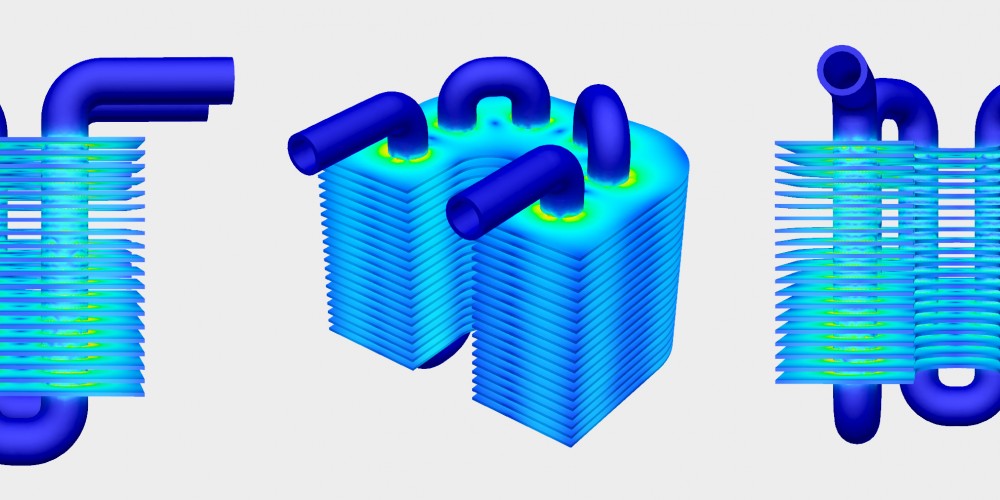

- The results were totally on par with the results from each study using Nastran In-CAD.

- I thought the results graphics looked cleaner and better in Fusion 360. Hey – I’m a visualization guy so I can’t help noticing that one even though a lot of designers won’t.

- I could do some cool stuff viewing ranges of results just by dragging on the legend. This made it really easy to evaluate complex results that happen inside the mesh.

Now I’ll leave it up to our Simulation gurus to expand on the simulation tools in another blog post (I’m looking at you, Eric!). But this is what I reaffirmed with this experience: Fusion 360 simulation works pretty great! In the hands of a designer or engineer, it can keep up with other tools just fine. And Autodesk isn’t done adding more capabilities to it either.

To anyone who has been thinking Fusion 360’s simulation was just a toy, you’re wrong. It’s a great solution for anyone who wants to improve their design with simulation and doesn’t already have simulation, or can’t justify the cost of the tools available inside their own CAD. This is true whether you’re using Inventor, SOLIDWORKS, Catia, Solid Edge, really any design tool out there. Many of the simulation tools offered traditionally didn’t run inside your existing CAD anyway, so using Fusion 360 for simulation is a workflow many users will already be comfortable with. The fact that it can consume your native CAD data without designers needing to export neutral formats is an added bonus.

As we were discussing our Jedi training on the trip home, I found this topped the list of things I wanted to share on the blog. I hope it makes you step back and think about your own Simulation solution (or lack thereof)! Go ahead, test out Fusion 360 alongside your existing simulation tools for a while and see what you think.