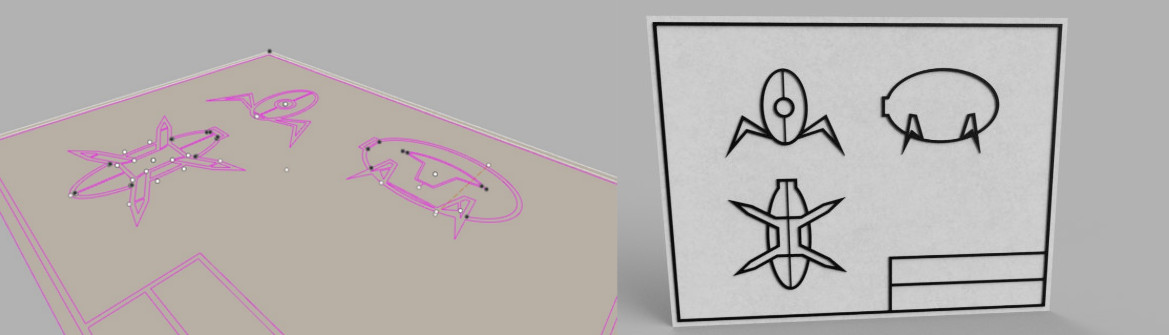

Hi! I am a new contributor to this blog, so let me introduce myself. My name is Daniel Douglas and I am a member of the Fusion 360 team, here at D3. I have a background in Drafting and Design, Robotics, and Education. Also, I am ecstatic about Aerospace Engineering, Space Exploration, Future Technologies, and Manufacturing Processes. Using these experiences and passions, I hope to be informative, inspiring, and helpful. Please don’t hesitate to comment with questions, corrections, suggestions, or just plain old conversation. Thanks for reading!

“Can you make a 3D model in AutoCAD,” the Plant Manager asked me, “so that the workers can better visualize this assembly?” There I was (2 ½ years ago), a novice Packaging Designer, working out of an old AutoCAD license. My drafting training had focused on traditional 2D drawings, with a smattering of SolidWorks, so I wasn’t overly excited at the prospect of modeling assemblies in the AutoCAD workflow.

After messing around with my basic AutoCAD, I realized that any model would have to be exported for rendering and/or animation. Then I began a hunt for free or low cost software solutions. After an hour of downloading and testing applications, I concluded that I needed an all-in-one software suite.

I needed an all-in-one software suite

As an Autodesk user, it didn’t take long for me to find and download Fusion 360. It was somewhat familiar AND it was free to try. With the help of YouTube, and a lot of pain, I began to learn the workflow of fledgling Fusion 360: it was awful. Of course, I was basically learning 3D design AND Fusion 360 at the same time. It was a trial-and-error learning experience, and it was not fun.

At that time, Fusion 360 was barely a year or two old and suffered from dozens of random and persistent bugs. Learning is not fun when your files disappear and your tools don’t consistently work (especially if they break the model). Fusion 360’s groundbreaking packaging of Modeling, Sculpting, Rendering, and Animation was exciting and useful, but in the words of my supervisor: “Fusion 360 is like a Swiss Army knife. It is a neat collection of tools, but if you want to cut down a tree, then you’d better use a chainsaw.”

Fusion 360 is like a Swiss Army knife

Regardless of the hiccups, I was amazed by the nearly nightly updates and patches. No glitch was left alone longer than a few days, but some patches made more bugs than they fixed. At times the workflow felt like a minefield: one wrong step and it blows up in your face. Despite the growing pains – both mine and Fusion 360’s – I could create part and assembly models, render attractive images, and make exploded view animations. That was exactly what I wanted. Just a reminder that learning is a lot of work, but is well worth the payoff.

Fast forward to today: Fusion 360 keeps getting more and more powerful. With the cloud-based file system, the ability to open any file type, and the refined team tools, collaboration has never been more accessible. The team at Autodesk keeps adding new tools and refining old ones. So far, they have built new environments such as Sheet Metal, Simulation (using Autodesk Nastran), and CAM (using Autodesk Inventor HSM or HSMWorks). Not to mention that they added support for EAGLE, a PCB design software, enabling a Fusion/EAGLE workflow and adding one more tool to the Product Designer’s toolbelt. Fusion 360 has evolved from a pocket-sized bag of tricks into a full workshop of professional tools.

Fusion 360 has evolved

These exciting new features, the rate of improvement, and Autodesk’s clear investment in Fusion 360 all lead to an obvious question: what is the plan for Fusion? Well, the answer has already been given. Autodesk is trying to hone Fusion 360 as tool for Industry 4.0. The goal is to create a piece of software that seamlessly bridges all departments and workflows, from Sales Engineering to Manufacturing, from Concept Design to Product Maintenance. Instead of a crazy web of compartmentalized data, stand-alone software packages, and expensive corrections, Autodesk envisions a world where every step of the design/product lifecycle is fluidly connected, thereby allowing unprecedented efficiency and innovation. I for one can’t wait to see Fusion 360 grow into that vision.

See Fusion 360 grow!